Pneumatic tools have revolutionized industries with their efficiency, strength, and adaptability. From construction to manufacturing, these tools play a pivotal role in enhancing productivity and refining operations. This comprehensive guide delves into the world of pneumatic tools, examining their applications, advantages, and significance across diverse industries while shedding light on their association with geogrid technology.

Defining Pneumatic Tools

Pneumatic tools, also known as air tools, harness the force generated by compressed air to execute a myriad of tasks. This comprehensive category includes pneumatic drills, nail guns, impact wrenches, sanders, and grinders, catering to various applications.

Advantages of Pneumatic Tools

The advantages of pneumatic tools are multifaceted. They boast higher power-to-weight ratios compared to their electric counterparts, resulting in lighter and more maneuverable tools without compromising performance. With simpler internal mechanisms, they exhibit extended durability, minimal maintenance needs, and resilience in harsh environments.

Where Pneumatic Tools Thrive

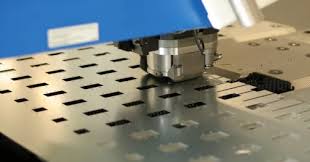

Pneumatic tools find utility across diverse sectors such as construction, automotive, manufacturing, woodworking, and aerospace. In construction, these tools are indispensable for drilling, nailing, riveting, and grinding tasks. In manufacturing, they streamline assembly lines and material handling processes.

Integration with Geogrid Technology

Geogrids serve as construction materials for soil stabilization and reinforcement. Pneumatic tools play a pivotal role in the geogrid installation by preparing surfaces, drilling holes, and securing geogrids in place. Tools like pneumatic drills and nail guns ensure precise and efficient installation, bolstering geogrid technology’s effectiveness in soil stabilization projects.

Applications and Relevance

The application of pneumatic tools spans a wide spectrum, encompassing tasks in metalworking, woodworking, automotive repair, construction, and more. For instance, in metalworking, pneumatic grinders and sanders offer precision and power for shaping and refining metal surfaces. In construction, tools like jackhammers and nail guns expedite tasks such as breaking concrete or securing materials.

Incorporating pneumatic tools amplifies efficiency and ensures precision across various applications, including the integral realm of geogrid technology in construction and soil stabilization projects.