Valves stand as the unsung heroes orchestrating fluid and gas movements in engineering and industrial domains, wielding significant influence over operational dynamics. Whether facilitating water flow in household plumbing or navigating intricate industrial processes, valves emerge as indispensable components. This manuscript delves into the intricate world of valve technology, unraveling its essence, mechanisms, and versatile applications.

Valves Unveiled: What Are They and How Do They Function?

Valves epitomize mechanical finesse, engineered to regulate fluid or gas flows by opening, closing, or modulating passages. They operate through diverse mechanisms such as manual control, pneumatic or hydraulic actuation, and automated systems. Essentially, valves govern flow rates, pressures, and flow directions within systems, ensuring operational precision.

Valve Spectrum: Types and Tactical Utilizations

Valves present a vast array of designs tailored to specific requisites. Common variants encompass gate valves, globe valves, ball valves, butterfly valves, and check valves, each serving distinct purposes from isolation and regulation to backflow prevention. For instance, gate valves excel in on/off control for pipelines, while ball valves offer rapid shut-off in high-pressure scenarios. Familiarity with each valve type’s characteristics proves pivotal for selecting the appropriate one for any given application.

Valves in Industrial Arena: Custodians of Operational Excellence

Within industrial landscapes, valves emerge as linchpins in process control systems, steering the flow of liquids, gases, and steam. Industries spanning oil and gas, petrochemicals, pharmaceuticals, and water treatment heavily rely on valves to uphold operational efficiency and safety standards. Valves facilitate precise regulation of parameters like temperature, pressure, and fluid composition, ensuring optimal performance and regulatory compliance.

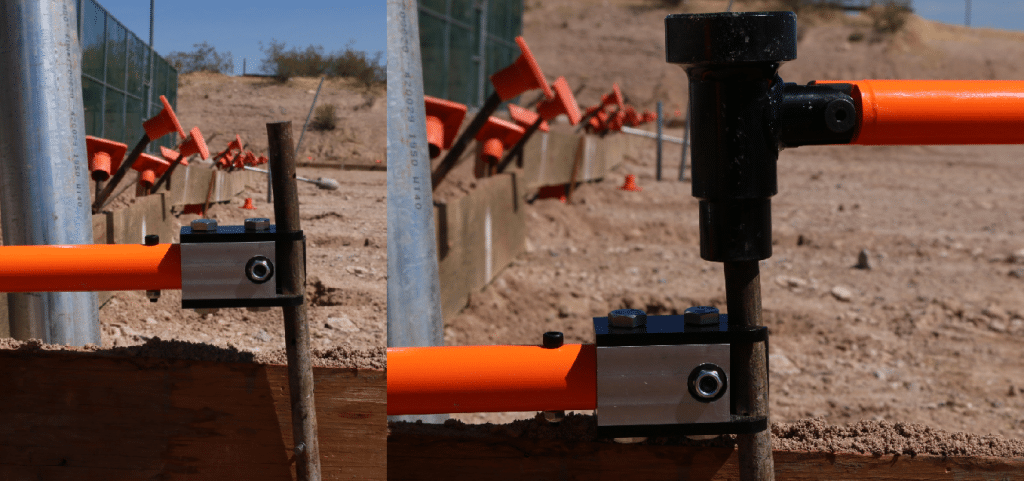

Convergence of Valve Technology and Geonet Innovations: Catalyzing Technological Progress

Geonet innovations wield substantial influence on valve technology, propelling strides in materials, designs, and automation. Materials like corrosion-resistant alloys and polymers fortify valve durability and reliability, particularly in challenging operating environments. Furthermore, integration of smart technologies like sensors and actuators enables remote monitoring, predictive maintenance, and enhanced control capacities. Geonet’s sway fuels continual refinement and adaptation in valve technology to meet evolving industrial requisites.

Valve technology stands as the cornerstone of fluid and gas control systems across diverse industries. From fundamental household plumbing to intricate industrial operations, valves adeptly manage flow, pressure, and direction with precision and dependability. Understanding the diverse array of valve types and their applications proves pivotal for optimizing system performance and ensuring safety protocols. Moreover, amalgamation of valve technology with geonet innovations propels the industry forward, ushering in smarter, more efficient, and resilient systems. Embracing these synergies ensures that valve technology remains at the forefront of industrial innovation.

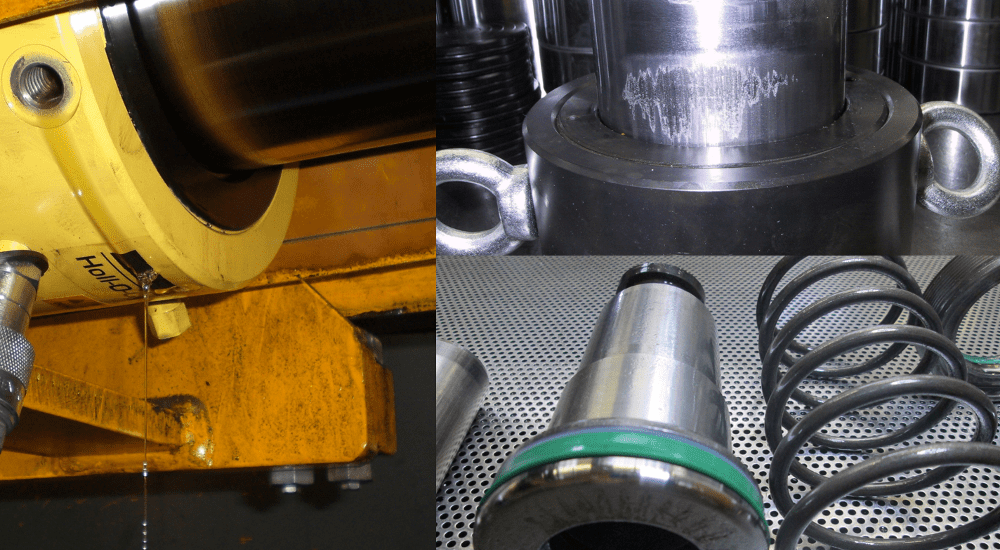

air compressor air release valve

The air release valve on an air compressor automatically vents excess air pressure from the system, preventing dangerous over-pressurization. This safety feature protects the compressor and downstream equipment by maintaining safe operating pressures within the compressed air system.